Introduction

Drainage is a critical component affecting the hygienic performance of commercial food preparation business. Effective drainage helps to mitigate hazards from the external environment and is central to the safe and hygienic operation internally. Within the food production facility, surface liquids represent potential hazard of microbiological contamination. Liquids may be part of the cleaning process, or

may originate from specific equipment discharge points, or be simply the result of an accidental spillage. Quite often the liquids contains other components – organic matter being predominant. Floor drainage components cater for these situations through three core functions - interception, conveyance of fluids, and ability to act as a barrier.

Effective cleaning of drainage in commercial food preparation business reduces risk of contamination and spoiling of food during preparation, processing, and storage. The main objective of cleaning is to remove soil to obtain clean surface and thereby reduce number of microorganisms. A further reduction of microorganism can be obtained by disinfection step.

Principles of cleaning

There are two different types of surface to be cleaned:

Product contact surface

All equipment that itentionally or unitentionally (e.g. due to splashing) comes to contact with final product or from which product or condensate may drain, drop or be drawn into the main product or product container.

Non product contact surface

All other exposed surfaces, including surfaces associated with equipment, such as support structures, control panels and external surfaces. It also includes surfaces related to the manufacturing environment, such as floors, walls and drain channels.

We also differenciate cleaning process as whether it is applied dry or wet.

Dry cleaning

Dry cleaning is essentially a mechanical removal of soils using sweeping, brushing, wiping and vacuuming. Enviroments typically to be cleaned by dry methods include plants which are producing flour, cocoa, dry milk products, dry soups and dry infant formulas.

Wet cleaning

Wet cleaning involves application of fluids (usually water based) to achieve the desired cleaning result. This can be applied to Open Plant Cleaning (OPC): surfaces to be cleaned have to be accessible to fluids. In addition, some components may be physically removed from production area and cleaned separately

Cleaning out of place (COP). Drainage systems require wet cleaning.

The last is a distinction between whether the cleaning process is done manually or automatically.

Manual cleaning

Manual cleaning is generally considered as labour intensive and, therefore often expensive. The manual tools should be hygienic – resistant to applied chemicals and suitable for a specific operation. On top of it; operators should be properly trained to be able to perform cleaning as expected to achieve clean surfaces.

ACO drainage has all elements of hygienic design that makes cleaning of ACO drainage much easier and faster when compared to competitive products.

Automatic cleaning

Utensils and dismantled parts of equipment are cleaned and disinfected automatically in industrial washing machines, tray or tunnel washers (automatic COP). CIP is also defined as automatic cleaning system.

Cleaning chemicals

There are three main classes of cleaning compounds:

- detergents

- alkalies

- acids

- disinfectants/sanitizers

Detergents

This broad group of chemicals is widely used in households and in food industries brings different type of soil from surfaces into cleaning foams and emulsions that could be easily rinsed off.

Alkalies

Alkaline compounds are effective for dissolution of proteins and removal of fats. Example of alkalies are sodium hydroxide (caustic soda) and potassium hydroxide. These compounds are hazardous to personnel and mostly used in CIP – automatic dosing system is recommended.

Acids

Acids, both organic and inorganic, are commonly used for removal of mineral deposits, such as: hard water scale or milk stone. Acids are potentially corrosive to construction materials and must be used with care.

When chemical cleaning is performed, it is neccessary to use low-pressure sprays, foam or gel. Foam and gel are more viscous than sprayed agents and preferred as they are not prone to aerosol formation. Selection of the correct detergent for given application should be always done in co-operation with the detergent supplier.

Disinfectants/sanitizers

In case of high risk area‘s or production areas with microbiological sensitive products, the floors and drain systems should be sprayed with disinfectants/sanitizers, which will reduce the contamination risk even more. The disinfectants/sanitizers will kill remaining micro-organisms, according to the required specifications.

The plant downtime and labour associated with cleaning is major cost of any food processing operation.

Sources of soil

Primary source of soil is from processed food product itself. Microbiological bio- films mainly contribute to the soil build ups on drainage surfaces. These films vary in their solubility depending upon such factors as heat effect, age, dryness, time, etc. It is essential that personnel involved in the cleaning process design have understanding of the nature of the soil to be removed before selecting a detergent and cleaning method. The rule of thumb is that acid cleaners dissolve alkaline soils (minerals), and and detergents dissolve acid soils and food wastes (proteins).

Overview with recommended cleaning procedures for drainage

These instructions are for guidance only. Always follow manufacturer's instructions.

All procedures have to be verified and adjusted to the application specifics.

Frequency | Procedure | Physical agents | Chemical agents | Examples of chemical cleaning agents suitable for ACO stainless steel drainage |

Daily | Removal of organic deposits (fats, proteins, saccharides and polysaccharides) |

|

(sodium hydroxide, potassium hydroxide)

| Standard chemical agents used for floor cleaning should be sufficient (should be validated) Oxofoam, Endorochlor (Diversey) |

Weekly | Removal of inorganic deposits that could promote very resistent biofilms | Mechanical abrasive methods – polishing |

|

|

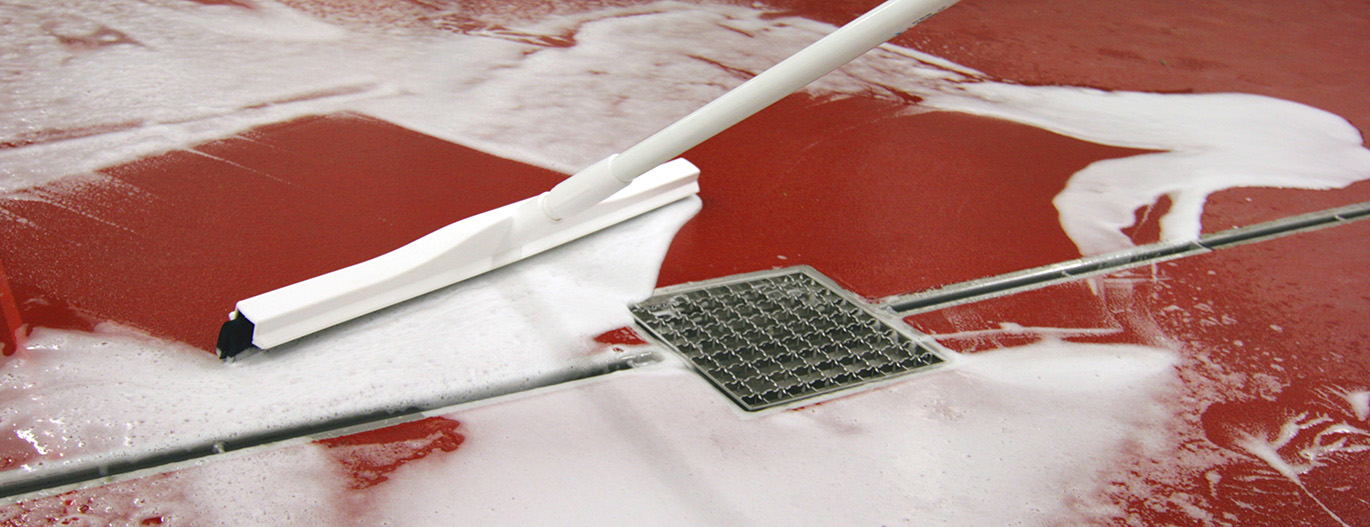

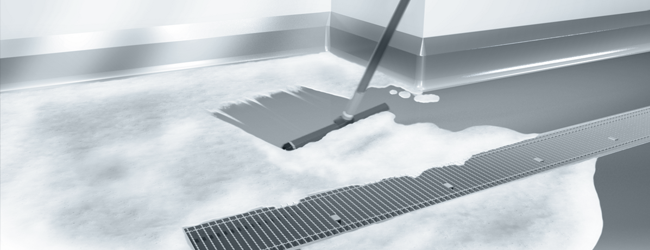

Note | Removal of rinse water residues | Removal of excess water with a squeegee | Alcohols (isopropylalcohol, ethanol) | Chlorine tablets (Suma Tab D4 by Diversey) are often added to the water in foul trap in microbial sensitive production area‘s |

Any cleaning procedures, including those recommended by equipment suppliers, must be properly validated at the equipment, where it will be applied and on the soil that could be expected even after certain time of usage.

Always follow manufacturer's instructions to avoid damage to the equipment.

Material Resistance

Note:

Concentration levels and length of exposure have a direct influence on the resistance of stainless steel to certain chemicals. Each application should therefore be carefully reviewed to determine the suitability of stainless steel.

Data presented are used as a guide only.

1 = Very good service to operating limit of material 2 = Moderate service 3 = Limited or variable service 4 = Unsatisfactory | AISI 316 L Stainless | AISI 304 Stainless | EPDM | NBR | FPM | TPEV |

Acetone | 1 | 1 | 1 | 4 | 4 | 1 |

Acetic acid (diluted) 30% | 1 | 1 | 1 | 2 | 2 | 1 |

Acetic acid 100% | 1 | 1 | 1 | 3 | 3 | 1 |

Acetic acid anhydride | 1 | 1 | 2 | 3 | 4 | 2 |

Aluminium chloride | 4 | 4 | 1 | 1 | 1 | 1 |

Aluminium sulfate | 1 | 4 | 1 | 1 | 1 | 1 |

Ammonium carbonate | 1 | 1 | 1 | 4 | 2 | 1 |

Ammonium chloride | 2 | 3 | 1 | 1 | 1 | 1 |

Ammonium hydroxide | 1 | 1 | 1 | 4 | 2 | 1 |

Amyl chloride | 1 | 1 | 4 | 4 | 1 | 4 |

Anilin | 1 | 1 | 2 | 4 | 3 | 1 |

Anilin hydrochloride | 4 | 4 | 2 | 2 | 2 | 2 |

Barium chloride | 2 | 2 | 1 | 1 | 1 | 1 |

Barium hydroxide | 1 | 1 | 1 | 1 | 1 | 1 |

Benzaldehyde | 1 | 1 | 1 | 4 | 4 | 1 |

Benzene | 1 | 1 | 4 | 4 | 1 | 4 |

Benzoic acid | 1 | 1 | 4 | 4 | 1 | 1 |

Borax | 1 | 1 | 1 | 2 | 1 | 1 |

Boric acid | 1 | 1 | 1 | 1 | 1 | 1 |

Bromine | 4 | 4 | 4 | 4 | 1 | 4 |

Bromine chloride acid | 4 | 4 | 1 | 2 | 1 | 2 |

Bromine hydrogen acid | 4 | 4 | 1 | 4 | 1 | 2 |

Bromoethylene | 1 | 1 | - | - | - | - |

Butanol | 1 | 1 | 4 | 1 | 1 | 3 |

Butyl acetat | 1 | 1 | 2 | 2 | 4 | 3 |

Butyric acid | 1 | 1 | 2 | 4 | 4 | 3 |

Calcium bisulfate el sulfite | 1 | 1 | 4 | 1 | 1 | 1 |

Calcium chloride | 2 | 2 | 1 | 1 | 1 | 1 |

Calcium hydroxide | 1 | 1 | 1 | 1 | 1 | 1 |

Calcium hypoklorite | 2 | 3 | 1 | 3 | 1 | 3 |

Carbon disulfide | 1 | 1 | 4 | 4 | 1 | 3 |

Carbon tetrachloride | 1 | 1 | 4 | 3 | 1 | 4 |

Chloracetic acid (mono) | 4 | 4 | 2 | 4 | 4 | 2 |

Chloride | 4 | 4 | - | - | - | - |

Chloril acid | 4 | 4 | 1 | 4 | - | 3 |

Chlorine (dry) | 1 | 1 | 1 | 2 | 1 | 4 |

Chlorobenzene | 1 | 1 | 4 | 4 | 1 | 4 |

Chloroform | 2 | 2 | 4 | 4 | 1 | 4 |

Chlorosulfonic acid | 2 | 3 | 4 | 4 | 3 | 4 |

Copper chloride | 2 | 2 | 1 | 1 | 1 | 1 |

Copper nitrate | 1 | 1 | 1 | 1 | 1 | 1 |

Copper sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Ether | 1 | 1 | 3 | 4 | 3 | 3 |

Ethyl chloride | 1 | 1 | 1 | 1 | 1 | 3 |

Fatty acid | 1 | 1 | 4 | 2 | 1 | 1 |

Fluorine (dry) | 1 | 1 | - | - | - | - |

Fluorine hydrogen acid | 4 | 4 | 2 | 4 | 1 | 4 |

Formaldehyde | 1 | 1 | 1 | 2 | 1 | 1 |

Formic acid | 1 | 1 | 1 | 2 | 3 | 2 |

Furfural | 1 | 1 | 2 | 4 | 4 | 4 |

Gallic acid | 1 | 1 | 2 | 2 | 1 | 2 |

Hydrochloric acid | 4 | 4 | 1 | 4 | 1 | 1 |

Hydrogen peroxide | 1 | 1 | 3 | 4 | 2 | 3 |

Iodine (wet) | 4 | 4 | 2 | 2 | 1 | 2 |

Lead acetate | 1 | 1 | 1 | 2 | 4 | 1 |

Magnesium chloride | 2 | 2 | 1 | 1 | 1 | 1 |

Magnesium sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Mercury | 1 | 1 | 1 | 1 | 1 | 1 |

Methanol | 1 | 1 | 1 | 1 | 3 | 1 |

Methyl chloride | 1 | 1 | 3 | 4 | 1 | 3 |

Methylene chloride | 2 | 2 | 4 | 4 | 2 | 4 |

Natphalene | 1 | 1 | 4 | 4 | 1 | 1 |

Nickel chloride | 2 | 2 | 1 | 1 | 1 | 1 |

Nickel sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Nitric acid | 3 | 3 | 3 | 4 | 1 | 4 |

Oxalic acid | 3 | 3 | 1 | 2 | 1 | 2 |

Perchloric acid | 4 | 4 | 2 | 4 | 1 | 1 |

Phorsphor acid | 1 | 1 | 2 | 4 | 1 | 1 |

Picric acid | 1 | 1 | 2 | 2 | 1 | 2 |

Potassium bromide | 1 | 1 | 1 | 1 | 1 | 1 |

Potassium carbonate | 1 | 1 | 1 | 2 | 1 | 1 |

Potassium chlorate | 1 | 1 | 1 | 1 | 1 | 1 |

Potassium cyanide | 1 | 1 | 1 | 1 | 1 | 1 |

Potassium hydroxide | 1 | 1 | 1 | 2 | 2 | 1 |

Potassium nitrate | 1 | 1 | 1 | 1 | 1 | 1 |

Potassium permanganate | 1 | 1 | 1 | 3 | 1 | 1 |

Potassium sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Potassium sulfide | 1 | 1 | 1 | 1 | 1 | 1 |

Potassiumchloride | 2 | 2 | 1 | 1 | 1 | 1 |

Prophylene dichloride | 1 | 1 | 4 | 4 | 1 | 4 |

Sal ammoniac | 2 | 3 | 1 | 1 | 1 | 1 |

Silver nitrate | 1 | 1 | 1 | 2 | 1 | 1 |

Soda (ash) | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium acetate | 1 | 1 | 1 | 2 | 4 | 1 |

Sodium bicarbonate | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium bisulfate | 1 | 3 | 1 | 2 | 1 | 1 |

Sodium bisulfite | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium bromide | 2 | 2 | 1 | 3 | 1 | 2 |

Sodium chlorate | 1 | 1 | 1 | 2 | 1 | 1 |

Sodium chloride | 4 | 4 | 1 | 1 | 1 | 1 |

Sodium cyanide | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium fluoride | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium hydroxide | 1 | 1 | 1 | 2 | 2 | 1 |

Sodium hypoklorite | 4 | 4 | 2 | 2 | 1 | 1 |

Sodium nitrate | 1 | 1 | 1 | 2 | 2 | 1 |

Sodium sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium sulfide | 1 | 1 | 1 | 1 | 1 | 1 |

Sodium sulfite | 1 | 1 | 1 | 1 | 1 | 1 |

Stannicous chloride | 2 | 3 | 2 | 1 | 1 | 2 |

Sulfur | 1 | 1 | 1 | 4 | 1 | 1 |

Sulfur chloride | 1 | 1 | 4 | 3 | 1 | 3 |

Sulfur dioxide | 1 | 2 | 1 | 4 | 1 | 1 |

Sulfuric acid | 4 | 4 | 2 | 4 | 1 | 3 |

Sulfurous acid | 1 | 3 | 2 | 2 | 1 | 2 |

Tionyl chloride | 1 | 1 | 4 | 4 | 1 | 4 |

Toluene (toluol) | 1 | 1 | 4 | 4 | 1 | 4 |

Trichloroethylene | 1 | 1 | 4 | 3 | 1 | 4 |

Turpentine | 1 | 1 | 4 | 1 | 1 | 4 |

Xylene (xylol) | 1 | 1 | 4 | 4 | 2 | 4 |

Zinc sulfate | 1 | 1 | 1 | 1 | 1 | 1 |

Sealing material information

EPDM

(ethylene propylene diene monomer)

Black sealing rubber ring, which is suitable for most applications where there are no oil or petrol residues in the waste water.

NBR

(acryl nitrile-butadiene rubber)

Black sealing rubber ring which is suitable for waste water applications where there are petrol or oil residues. NBR is not resistant to solvents and high temperatures.

Sealing materials | ||||

EPDM | NBR | FPM (Viton®) | TPEV | |

Colour | black | black | green | red |

Temperature range | -50 / +130 / +150 °C | -30 / +80 / +100 °C | -20 / +200 / +300 °C | -35 / +120 / +140 °C |

Resistance | ||||

Water | excellent | good | good | excellent |

Chemicals | ||||

Acids | good | fair | excellent | good |

Bases | good | fair | excellent | excellent |

Benzene/Petrol | unsatisfied | excellent | excellent | limited |

Oils | ||||

ASTM Oil No. 1 | unsatisfied | excellent | excellent | limited |

ASTM Oil No. 3 | unsatisfied | excellent | excellent | limited |

Ozone & weather stresses | good | limited | good | good |

To be sure of suitability for special applications please consult exact seal material features within ACO installation guide.